Biogas plant is a plant for energy production from biomass ; these renewable sources to be used to feed the digester are composed of organic substances that can be degraded anaerobically to produce biogas and biofertilizers. Anaerobic digestion is the degradation of organic substances by microorganisms under anaerobic conditions . Anaerobic treatment is advantageous in that the biogas is used in a cogenerative system for the production of electricity and heat , in addition to producing a biofertilizer with very good agronomic properties.

Esquema

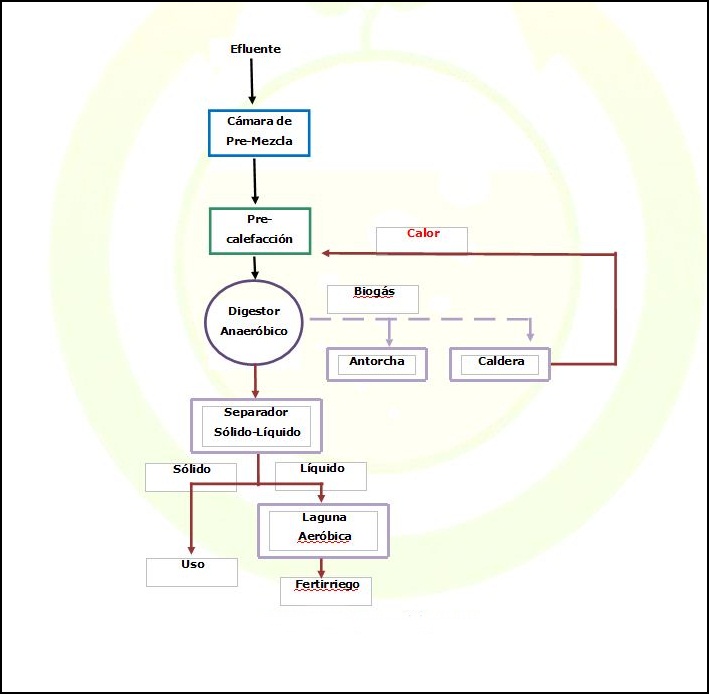

The plant in question is able to produce biogas through anaerobic digestion of effluents pigs , cattle, poultry , MSW , silage , etc and obtain electrical and thermal energy from the combustion of biogas in cogenerative system. The reception and pre – treatment will be the first compartment of the plant and will aim to get the biomass and feed throughout the day to the next phase of maceration. The effluent will be collected in a pre – load chamber , made of reinforced homigón.

The mix of organic matrices , mixed and homogenized with the mixer pump will be sent to anaerobic digestion controlled high performance . Anaerobic digestion will consist of one digester , called anaerobic or primary , which will be produced under conditions of controlled temperature homogenization and the degradation of the organic substance and the production of biogas. The degradation of biomass by microorganisms under anaerobic conditions takes place in the anaerobic digester and termofilia conditions at a temperature close to 50 ° C. The primary digester will be constructed in reinforced concrete conical bottom and will be thermally insulated to prevent heat loss stop.

The mixture of the primary digestate in the digester is guaranteed for one (1 ) vertical agitator installed on the roof of the reactor , consisting of a mechanical vertical shaft equipped with a motor and gear motor to work in classified areas ATEX with two rotors, whose task will be the mixing and eventual break floating crusts which form on the surface , while ensuring an optimal surface homogenisation and increased performance degradation.

The digestate is extracted with a pump and sent to the next storage or other receiver. Digestate extraction is carried out with pipe positioned in the center of the digester at the lowest point of the conical bottom; such caution for the manutención reactor continues to allow removal of the coarser material and / or inert that should be present inside the digester naturally tend to accumulate in the middle and on the bottom. The biogas produced in the anaerobic process is collected in pipes at constant pressure (about 16 ÷ 20 mbar ) and , after treatment , is sent to the engine cogeneration or torch. Biogas accumulated in the upper portion of the anaerobic digester ( around 280 m3 medium pressure of 16 ÷ 20 mbar ) to leave the anaerobic digester through a pipe located at the top of the roof slab . This pipe is made of stainless steel and embedded in the concrete slab . The digester will be equipped with a security system consisting of one (1 ) mechanical overpressure valve (calibrated to intervene 23mbar ) and one (1 ) Valve Vacuum Breaker (calibrated to intervene at 10 mbar ) to be located on the upper slab (roof) of the digester.

On leaving the anaerobic digester , biogas will be subjected to a first separation treatment of condensate through the passage in a condensate trap . This will consist of a special tank made of stainless steel. The tank will have a hydraulic valve ( calibrated 50mbar ) for continuously discharging the codensados biogas outlet and , in case of jamming . The condensate trap will be installed on top of the anaerobic digester in line after the intake pipe

Washing soda It is anticipated that the biogas is purified within a specific treatment section . Biogas washing a solution of sodium hydroxide to be applied countercurrent to the flow of the biogas is used. The presence of the reduction biogas desulfurization ensure that the latter may be sent to the combustion without causing deterioration cogenerative motor.

Before cogeneration, biogas will be sent to a battery dry to cool, composed of a heat exchanger and cooling unit (chiller type) .Such system will allow the removal of the condensate before feeding biogas engine cogeneration addition of a further reduction of hydrogen and improved operating conditions cogeneration engine. In preceding the boiler area , a centrifugal blower compressed biogas to carry the necessary pressure to feed the boiler. Also this second biogas compression station will consist of a centrifugal blower, located on a slab , which respect the regulations provided for installation in hazardous areas classified ATEX explosion . The boiler is needed to heat the digester at baseline ( methane ) and is in operation with biogas to maintain the temperature . Hot water is used in the digester heating circuit . Any excess biogas , for different reasons, could not be sent to the co – generation is a torch will burn up fitted with a manual on

After the solid-liquid separation of digestate , the solid fraction will stock for production of solid Biofertilizer (Biosol), while the liquid will be directed to the corresponding stock to then be used in fertigation .

Español

Español Português do Brasil

Português do Brasil